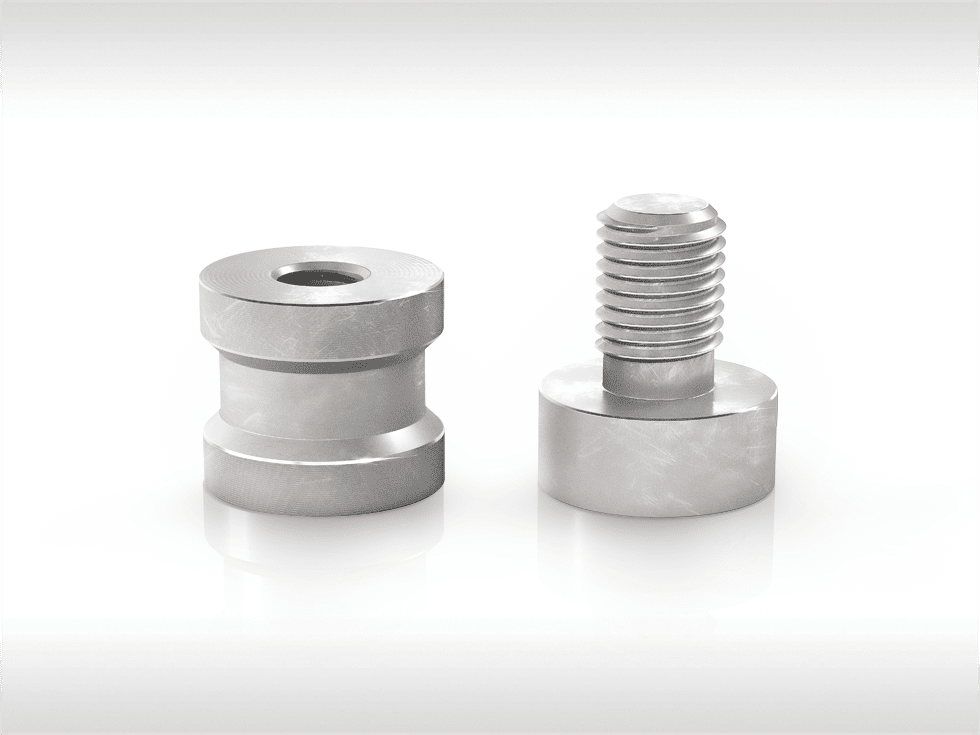

ERNI PowerElements

ERNI PowerElements can be used essentially anywhere where you are dealing with “power” sourcing capabilities, namely high current on the Printed Circuit Board (PCB). They not only transmit high current but can also protect the PCB from mechanical stresses.

Screwed fuses, relays and conductor rails can be connected and fixed with the PowerElements.

ERNI PowerElements are available with solid pressfit zones or for SMT soldering for the acceptance of high torques and optimum current transmission.

Technical Support

Jacarem has been An ERNI distributor since 2006, so our team have an abundance of knowledge to assist with your ERNI PowerElements designs.

Applications

- Battery management systems and power electronics in automotive applications.

- Drives and inverters in industrial automation

- Central electrical systems for agriculture and contruction machines

- Inverters for the solar industry

- Medical technology.

Thanks to a current carrying capacity of up to 500 amperes and high mechanical resilience, ERNI PowerElements are ideally suited for applications in which there are robust connections required for supplying high power.

Enquire About This Product

"*" indicates required fields

For further information please contact our team of technical experts who can assist you with your ERNI PowerElements requirements and find the best solution for your application. If you require a price or lead time, please e-mail [email protected] or phone 01494 791336.