Thermocouple feedthroughs are crucial in scenarios where traditional thermometers are impractical or continuous data recording is necessary. In vacuum settings, such as vacuum gauges and gas turbine exhausts, thermocouple vacuum feedthroughs excel in providing temperature readings. Similarly, in pressure chambers, thermocouple pressure feedthroughs find their application, aiding in precise temperature monitoring in diverse settings like diesel engines, fuel tanks, and laboratory environments.

Unlike traditional thermometers, a thermocouple feedthrough calculates temperature indirectly through a thermoelectric voltage resulting from a temperature gradient along the conductor. By utilising two dissimilar metals that conduct electricity at different rates, a junction is formed at one end of the cable. This junction generates a voltage proportional to the temperature, enabling temperature determination by measuring the voltage between the wires at the opposite end of the junction.

The insulation between the metals, except at the junction, is critical for accurate readings. Any lack of insulation can lead to inaccuracies in temperature measurements. The thermoelectric voltage produced at the junction is then transmitted along the entire length of the thermocouple alloy or compensating material, ensuring precise temperature data transfer from the internal chamber to an external instrument.

In summary, thermocouple feedthroughs play a vital role in enabling accurate temperature monitoring in vacuum and pressure environments, offering a reliable solution for temperature measurement challenges.

Applications for Thermocouple Seals

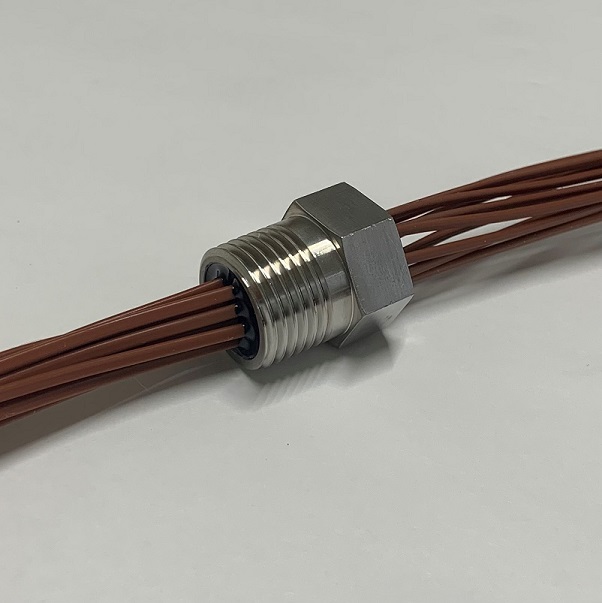

Thermocouple feedthroughs are carefully engineered and manufactured to ensure electrical isolation and hermetic integrity over a broad range of operating conditions and temperatures.

Our thermocouple vacuum feedthroughs are used in a variety of applications, including:

- Fuel Tanks

- Aerospace

- Lab Settings

- Gloveboxes

- Vacuum Gauges

- Gas Turbines

- Industrial Equipment

- Power Generation Control

- Semiconductor Equipment

- LED & Solar Processing Equipment

Why Contact Jacarem for Thermocouple seals?

The thermocouple feedthroughs we offer are hermetically sealed and customisable to meet your specific application requirements. We can create sealed thermocouples of any length with the ability to seal both stranded and solid conductor thermocouples using various insulation materials such as glass braid, PVC, and Teflon. Additionally, we specialise in different types of thermocouple connectors including D-sub connectors, standard disconnects, and circular mil-spec connectors.

Each thermocouple vacuum feedthrough constructed contains thermocouple contacts and/or wire within the hermetic seal, ensuring minimal errors in your application. Our range of feedthroughs is designed to withstand extreme conditions while remaining tailored to your needs. They are engineered to resist mechanical shock failure and vibration, offering proven reliability.

While most of our thermocouple vacuum feedthroughs are customised, we also provide a selection of stock seals for your convenience. Feel free to contact us to explore personalised solutions for your specific application requirements.