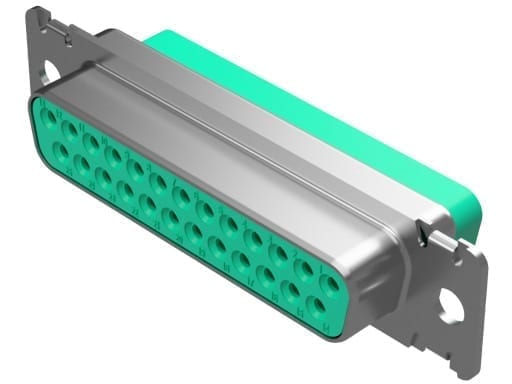

Hermetic Wire Sealed Feedthroughs

A hermetic wire seal feedthrough can be designed and produced for every industry from medical facilities and labs to airport equipment. Some more common applications are vacuum chambers / pressure chambers, glove boxes, air conditioning and refrigeration and space simulation equipment.

Our technical team can assist you with your hermetic wire seal requirements. Whether you require a standard feedthrough or something more custom, contact our team today by clicking on the blue button below.

Hermetically Sealed Wire Feedthroughs

Hermetic wire seal feedthroughs pass conductors in a wire harness through a chamber wall with no vacuum or pressure loss. An epoxy sealed wire feedthrough eliminates issues with voltage drop, contact resistance, and other electrical problems. An epoxy hermetically sealed wire feedthrough is a wise solution if you don’t need to disconnect at the bulkhead but instead have a ‘sealed for life’ feedthrough application.

Advantages of hermetically sealed wire feedthroughs

In addition to robust sealing, resistance to mechanical stresses and minimal electric losses, a huge advantage of hermetically sealed wire feedthroughs is their design flexibility. Engineers have no fixed limit on the number and gauge of conductors. Whether you have a few wires, hundreds or thousands of wires, the same conductor sizes or different conductor sizes, the design capabilities are endless (a wire feedthrough pick ‘n’ mix).

Wire feedthroughs often tend to offer space savings in new pressure and vacuum systems, as a greater number of conductors can be engineered to fit through. Wire feedthroughs allow for additional clearance for moving machine parts inside or outside the chamber because wire feedthroughs don’t protrude in the same way that connectors do.

Continuous feedthroughs can also be used in older systems when retrofitting is necessary. Adding new instrumentation or sensors to an existing chamber can be a time-consuming and difficult task when using standard connectors or when the opening of the chamber wall does not allow additional conductors. A wire seal feedthrough can be adapted to add more conductors to work with limitations in an existing system.

Hermetic Wire Seal Feedthrough Applications

Hermetic wire seal feedthroughs are used in many applications and industries.

We can design and produce wire seals for every industry from medical facilities and labs to airport equipment. Some more common applications are vacuum chambers / pressure chambers, glove boxes, air conditioning and refrigeration and space simulation equipment.

Whatever your application, our engineering team will be able to recommend the most suitable and economic solution for you.

Wire Seal Feedthrough Testing

Every hermetic wire seal is tested with pressure and / or helium leak tested. In addition, all hermetic wire seal feedthroughs are hipot and / or continuity tested to ensure the wire seal feedthrough is correctly wired. This ensures every wire seal we ship is robust.

You might wish to combine wires, connectors and cables on a flange. We can facilitate this for you and design a custom vacuum flange to your exact requirements, leak tested and ready for you to install into your application.

Finally, for further information or a quotation on custom hermetic wire seal feedthroughs, please contact us.

Enquire About This Product

"*" indicates required fields

If you would like further information, a sample or a quotation, please contact: [email protected] or phone 01494 791336. Our sales team will be happy to assist you with your project.