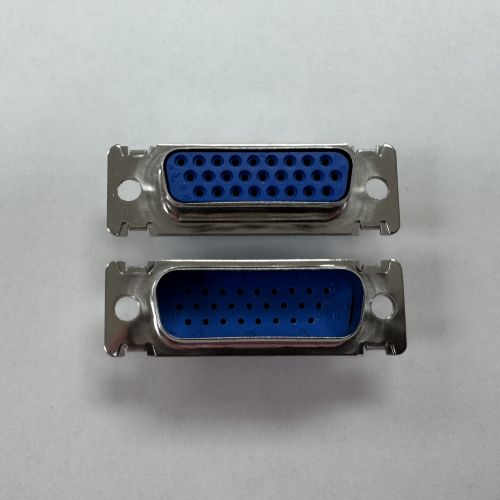

Vacuum Side High Density D Sub Cable Connectors

Vacuum High Density ‘Densi-D’ Connectors

The DD Series are military quality connectors designed for use in sheltered, mildly corrosive environments having a wide range of temperature, pressure and humidity changes. They are perfect for High Vacuum environments but can also be used in a large variety of other applications.

We usually carry the male and female parts in stock, offering next day delivery to our clients. We also

DD series, MIL-DTL-24308 / SAE AS39029 levels, removable contacts. Solder cup, crimp and straight and right angle 90° printed board contact terminations. Thermocouple contact options available. Six connector variants, 15 through 104 contacts.

For further information or a quotation, please Contact us.

Technical Specification

- Please refer to pdf for further data.

Vacuum Side High Density D Sub Cable Connectors

Our d-subs are suitable for high vacuum applications. Six standard contact variants are offered in arrangements of 15, 26, 44, 62, 78 and 104 contacts. Our connectors mate and are compatible with other high density D-subs conforming to MIL-DTL-24308. A wide variety of unique accessories are available.

D-Sub Plugs

- DD15M0000S/AA | 15 way

- DD26M0000S/AA | 26 way

- DD44M0000S/AA | 44 way

- DD78M0000S/AA | 78 way

- DD104M0000S/AA | 104 way

D-Sub Sockets

- DD15S0000S/AA | 15 way

- DD26S0000S/AA | 26 way

- DD44S0000S/AA | 44 way

- DD78S0000S/AA | 78 way

- DD104S0000S/AA | 104 way

The d-sub connectors can be supplied with removable precision machined crimp contacts.

- MC8022D/AA | Male crimp contact 22-30 awg

- FC8022D2/AA | Female crimp contact 22-30 awg

- MC8020D/AA | Male crimp contact 20 awg

- FC8020D2/AA | Female crimp contact 20 awg

Thermocouple contact options are also available for the high density removable contacts, please visit ‘D-Sub Thermocouple Contacts’ for more information.

If you require a vacuum sealed feedthroughs, we carry these in stock at Jacarem. Please click on the following link for further information: Sealed High Density D-Sub Feedthroughs

For further information or a quotation, please Contact us.

Data Sheets & Resources

Datasheet

DOWNLOADTechnical Characteristics:

Materials and Finishes

- Insulators: Glass filled polyester per ASTM D5927, UL94V-0, blue color.

- Contacts: Precision machined copper alloy.

- Contact Plating: Military performance – 50µin [1.27µm] gold over nickel plate. Industrial performance -gold flash over nickel plate. Other finishes available upon request.

- Interfacial Seal: Fluorosilicone rubber per MIL-R-25988.

- Shells: Steel with tin plate; zinc plate, stainless steel passivated. Other materials and finishes available upon request.

Electrical Characteristics

Contact Current Rating, Tested per UL 1977:

12 amperes, 2 contacts energized. 10 amperes, 6 contacts energized.

7.5 amperes, 26 contacts energized.

6.5 amperes, 62 contacts energized.

5.0 amperes, 104 contacts energized.

Initial Contact Resistance: 0.005 ohms maximum.

Proof Voltage: 1000 V r.m.s.

Insulation Resistance: 5 G ohms.

Clearance and Creepage

Distance [minimum]: 0.042 inch [1.06mm].

Working Voltage: 300 V r.m.s.

Enquire About This Product

"*" indicates required fields

If you would like further information, a sample or a quotation, please contact: [email protected] or phone 01494 791336. Our sales team will be happy to assist you with your project.