Hermetic connectors are important in maintaining the integrity of high-pressure, corrosive, or high-temperature environments. Hermetic connectors act as a barrier, ensuring a delicate pressure balance between different atmospheres.

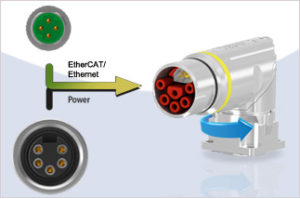

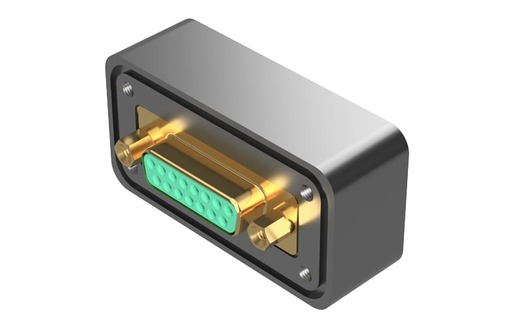

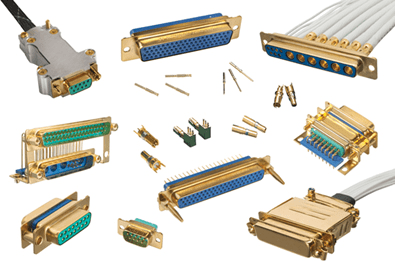

Jacarem presents a diverse selection of hermetically sealed connectors, including sealed USB and multipin mil-spec connectors. These connectors cater to various sectors like aerospace, automotive, military, and research, offering customisation to meet specific application requirements. Jacarem excels in creating epoxy hermetic seals for a wide range of connector types, ensuring reliability in critical environments.

Epoxy Sealed Hermetic Connectors

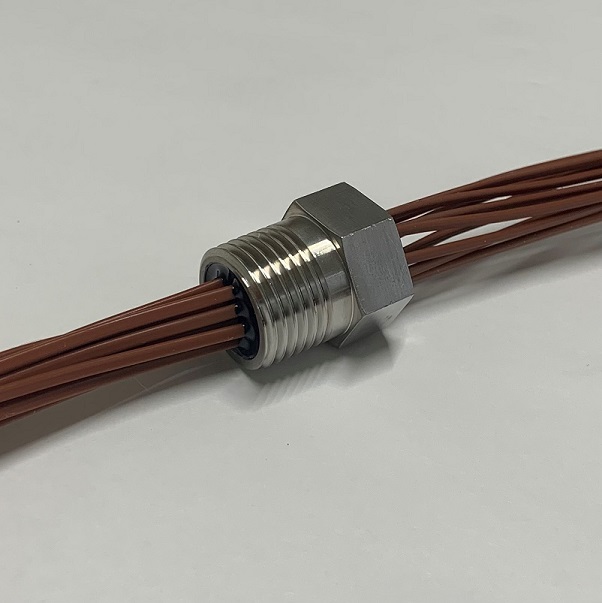

The evolution of sealing technology has revolutionised the way electrically conductive wires pass through bulkheads. Traditionally, wires were attached to pins sealed in ceramic or glass, posing cost and design limitations. However, with the advent of epoxy seal technology, these constraints have been overcome. Epoxy seals provide an uninterrupted passage, enhancing electrical reliability while reducing costs.

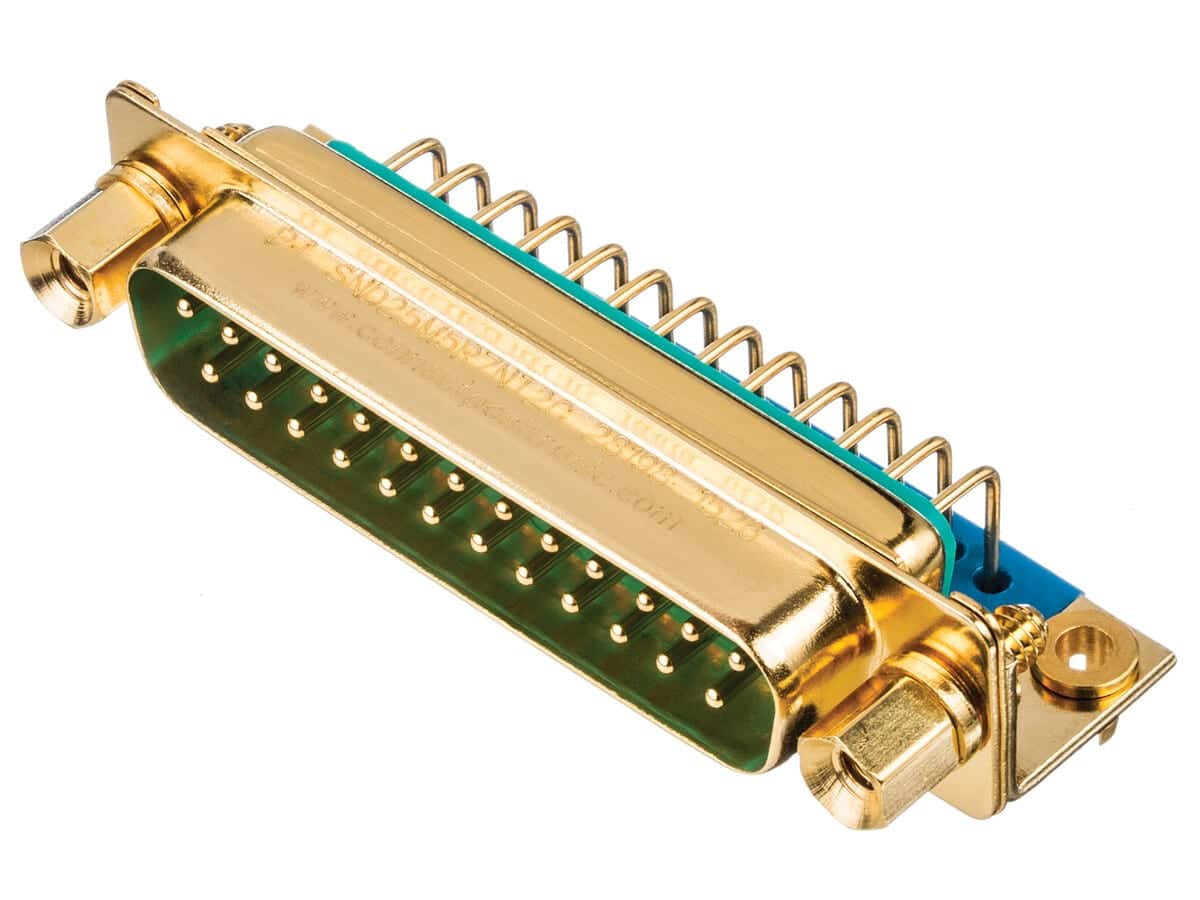

Compared to ceramic-to-metal and glass-to-metal seals, epoxy sealed connectors offer superior design flexibility, cost-effectiveness, and enhanced performance. They exhibit outgassing and leak rates on par with ceramic seals, making them suitable for both high and low-volume applications across various industries such as semiconductor manufacturing, automotive, aerospace, energy, and medical sectors.

Moreover, epoxy sealed connectors facilitate custom seal designs due to their moldability and flexibility. They are gradually replacing glass seals in diverse applications like fuel connectors, leak detection systems, and nuclear glove boxes. This shift is attributed to epoxy seals’ exceptional chemical resistance, compressive strength, and ability to withstand temperature variations and pressure fluctuations.

Hermetic Connector Applications

Hermetic connectors are gas-resistant and air-resistant. They are impervious to most gases and liquids, including alkalis, oils, acids, gasoline, hydraulic fluid, and jet fluid.

Hermetic connectors are frequently used in military applications like submarines and unmanned vehicles as well as industrial and commercial uses.

Hermetic connectors can thrive under even the harshest conditions and may be used with sensitive sensor and photographic equipment mounted to unmanned aerial vehicles that are exposed to extreme atmospheric pressure, rapidly changing temperatures, high altitude, and other severe weather.

They can withstand shock loads up to 100 Gs without loss of hermeticity and withstand extreme cold or heat without a loss of performance.

While we carry a range of stock connectors, many of our hermetic connectors are custom and engineered to meet very special requirements, such as submarine-safe connectors for feedthroughs and aircraft engine connectors.

Why buy from Jacarem?

We always place the highest priority on quality with every hermetic connector we engineer and ship. Every hermetic connector goes through rigorous testing after manufacture to ensure industry specifications are met. Before hermetic connectors are sent out, they go through thorough testing that includes dimensional inspection, helium leakage, electrical hipot, connector mateability, continuity, and visual workmanship.

We treat every order, even prototypes and low volume orders, with the utmost importance and strive to ship orders on time. With Jacarem, you can count on full support from the initial design stage through the life of your project with an experienced engineering team committed to providing the right hermetic connector for your application. Contact Jacarem today for assistance with a custom hermetically sealed connector if a standard hermetic connector isn’t suitable for your application.